Technology That Drives Better Mechanical Systems

At Finbarr Mechanical, technology is not an add-on. It is built into how we design, coordinate, and install every HVAC, plumbing, and piping system. By combining advanced 3D modeling tools with precise field layout technology, we help our clients reduce risk, shorten schedules, and deliver cleaner and more coordinated projects.

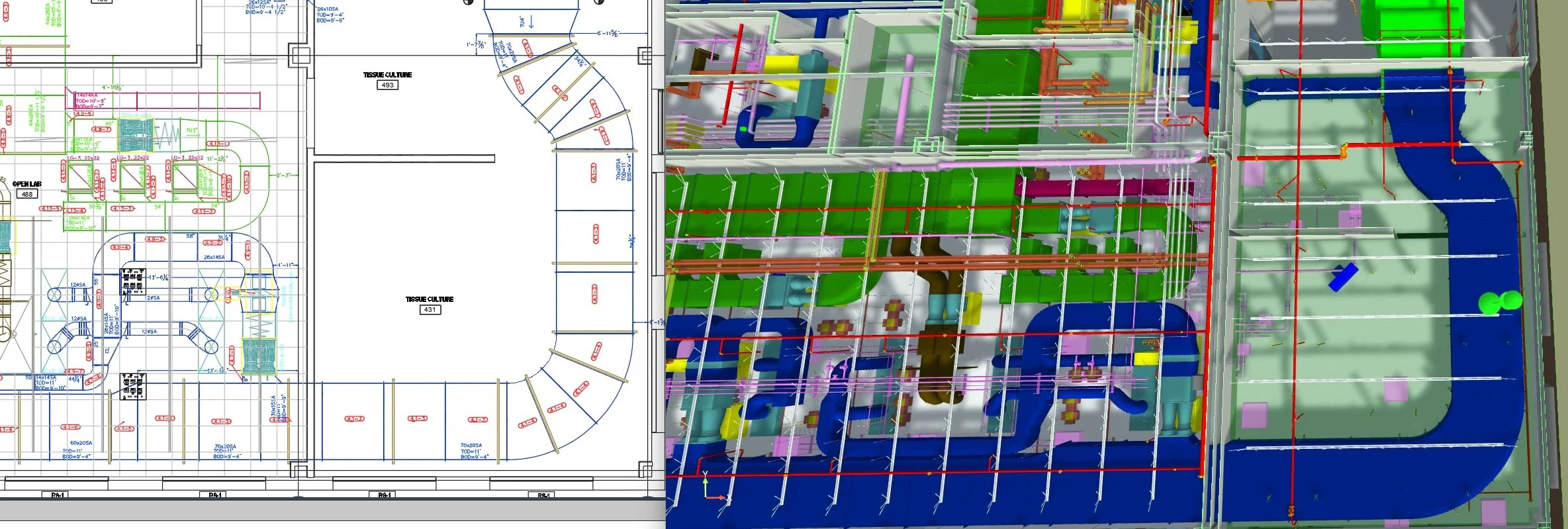

3D Design and BIM Coordination

We use Autodesk Revit to build intelligent 3D models of HVAC, plumbing, and piping systems that reflect how they will actually be installed in the field. Revit MEP allows our team to create fully parametric models and visualize mechanical layouts in 3D, improving design reviews, decision-making, and installation accuracy.

These models are then coordinated using Navisworks, Autodesk’s BIM platform for clash detection and model aggregation. Navisworks enables our team to combine architectural, structural, and MEP models, identify conflicts virtually, and resolve them before they become costly problems on site.

What this means for our clients:

Fewer conflicts in the field

Better coordination with other trades

Clear visual communication for owners, designers, and GCs

Higher confidence that what is drawn can actually be built

Fabrication-Ready Modeling

To bridge the gap between design and installation, we use Autodesk Fabrication tools such as Fabrication CADmep and related MEP fabrication products. These tools are purpose-built for mechanical, electrical, plumbing, and piping contractors and allow us to create detailed, constructible models with real-world manufacturer content.

Using Fabrication MEP software, we can:

Detail ductwork, hydronic piping, and plumbing systems to a fabrication level of detail

Generate accurate spool drawings and prefabrication sheets

Drive consistent fabrication workflows directly from the model

This approach supports a smooth transition from coordinated model to shop fabrication to field installation.

From Model to Field: Trimble S Series Layout

On site, our technology workflow continues with Trimble S Series robotic total stations. These high-accuracy instruments are designed for construction layout and use data from our 3D models to precisely stake out hangers, sleeves, equipment pads, and control points in the field.

By connecting our Revit and Fabrication models directly to Trimble layout, we can:

Push coordinated points from the model to the field controller

Perform layout with one-person robotic operation, reducing labor and rework

Maintain tight tolerances in mechanical rooms and congested ceilings

Capture as-built data that ties directly back to the BIM model

This model-to-field workflow helps ensure that what is coordinated in Navisworks is exactly what gets built on site.

Integrated Workflow and Real-World Results

Because all of our tools work together, including Revit for modeling, Fabrication MEP for constructible detail, Navisworks for clash detection, and Trimble S Series for field layout, we are able to offer a fully integrated mechanical delivery process.

For owners, general contractors, and design teams, this means:

Better predictability on schedule and cost

Fewer surprises in the field

Cleaner and more maintainable mechanical, plumbing, and piping systems

A digital model that accurately reflects the final installation

At Finbarr Mechanical, our investment in technology is driven by a commitment to deliver safer, smarter, and more efficient projects for every client we serve.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!